RUD COCKPIT

RUD COCKPIT | For a smart connection to your conveyor

Analyze critical operating conditions of the conveyor, identify hazardous operating conditions such as excessive heat, overfilled hoppers, unusual speeds, fix seated wheels, or critical tensioning distances.

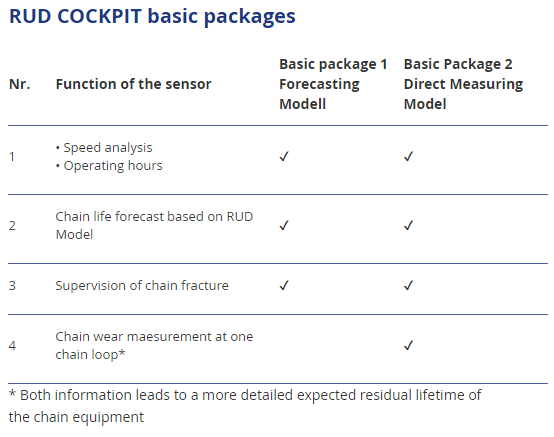

Improve process security through analysis: RUD COCKPIT Basic Package 1 provides a forecast of the remaining life of the chain equipment. RUD COCKPIT Basic Package 2 provides based on real-time chain elongation data (in percent) a detailed remaining chain equipment lifetime.

RUD COCKPIT supports preventative maintenance and service planning:

From the beginning you will get an accurate overview about the operating conditions of the conveyor. This allows conclusions about the remaining lifetime of chain equipment (due to different speeds, fix seted idlers, large number of chain loop revolutions etc.).

Areas of application of the RUD COCKPIT service

• Vertical Conveyors (e.g. bucket elevators)

• Horizontal Conveyors (e.g. scraper conveyors for de-ashing or other applications)

Focus:

• Analysation of critical operating conditions = transparency!

• Knowledge based consultancy for conveyors

• Fact based budget planning

Get information about:

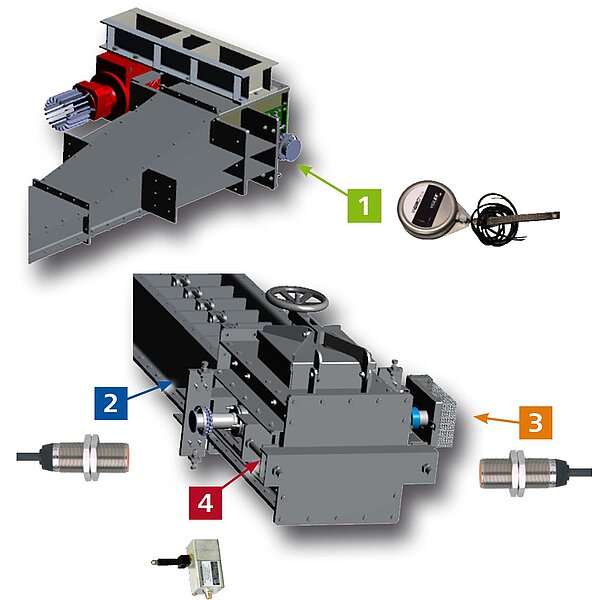

1. Speed analysis / Operation hours

(Provides information about the speed and the operating hours of the machine)

2. Chain life forecast based on RUD model

(Collect relevant informations)

3. Supervision of chain fracture

This sensor signalized if the tensioning shaft does not rotate)

4. Chain wear maesurment at on chain loop/ Chute elongation analysis

(Collect information about the residual tensioning distance)

5. Chain travel analyses

(Detect up climbing chain links)

6. Power analyses (hydraulic power only in a first step)

(Collects information about the power consumtion of the machine)

7. Temperature sensor

(Detects the temperature)

8. Overfilling of the discharge chute

(Collect signals caused by overfilling of the machine)

9. SOI detects fix seated submerged idlers

(These sensors signalized if the submerged idler do not rotate)

RUD COCKPIT | Your benefits at a glance

• Automated, continuous measuring

• No stops of the conveyor neccessary. No loss in production!

• Real time data. Validated information on every moment

• Fact based budget planning possible.

• Availability of data at all mobile devices for quick decisions.

• Web-based access to your data, no download of an App

• Permanent availability of the data through cloud application

• Core function is independent useability on any type of conveyor

• Safe access with personalised password

The RUD COCKPIT is able to:

• detect dangerous operating conditions (e.g. undue heat, over-filled chutes, unusual speeds, fixed seated idlers, tensioning distance consumed, etc.).

• Provides a prognostic of residual life time of the chain equipment (basic package 1) or provides a real time chain elongation in percentages (basic package 2).

• Supports predictive maintenance approaches and planning of services.

• Allows a conclusion why the lifetime of a chain equipment is reduced (due to various speeds, fixed seated idlers, etc.).

Web surface of RUD COCKPIT

• Managing all of your machines from one place

• Flexibility for new devices

• Easy login all over the world

• Responsive design for your mobile device

Following hardware end user devices can be used for the visualization of Alarms and the view of the web application:

• Desktop PC

• Smartphone

• Tablet Computer

• Laptop Computer

• It is a LAN / WLAN access necessary and a mobile network